- Contents

- Tool Case(suitcase) & Saw Case :Ms. Terauchi

- Unique Jig for cutting narrow grooves using a saw & Demo. :Ms. Takahashi

- Introduce the DeWALT table saw :Mr. Ueda

- Refined the compound miter cutting jig & Demo. :Ms. Moroi

- Introduce a tray using the compound miter cutting jig: Mr. Umemura

- Present his tool cabinet design: Mr. Dalton

Contents

Tool Case(suitcase) & Saw Case :Ms. Terauchi

Ms Terauchi purchased a cart capable of holding all her woodworking tools. It’s quite a splendid piece – the top opens, and underneath are drawers. Apparently, it was originally designed for make-up artists.

The other announcement was a saw case. Made of genuine leather, it has a simple rectangular shape, but magnetic sheets are attached to each of the two long sides. The idea is that when you place the saw into an open magazine and close it, the saw blade and case stick together magnetically. I believe its low price of 200 yen also contributed to it selling out in no time. Some members even placed custom orders for their preferred colours.

Unique Jig for cutting narrow grooves using a saw & Demo. :Ms. Takahashi

Ms Takahashi’s presentation concerns a tool for cutting narrow grooves using a saw blade. The saw blade incorporates an acrylic fence, with spacers inserted between them. This allows grooves to be cut at a position separated from the edge of the material by the thickness of the spacers. The saw handle is not used.

Introduce the DeWALT table saw :Mr. Ueda

Mr Ueda introduces the DeWALT table saw. The title of the presentation is ‘Rack & Pinion’. This refers to a type of gear where a round pinion gear meshes with a flat rack gear. This gear system is used to move the fence that slides left and right across the table, which apparently contributes to its high precision. Flat rack gears are positioned at the front and rear edges of the table. Turning the round pinion gears, located at the front and rear lower sections of the fence using a lever, moves the fence sideways. In essence, there are two gears per position, much like two wheels connected by axles running on two parallel rails. Additionally, the article covered methods for creating custom insert plates to surround the saw blade, including how to make zero-clearance insert plates. Compared to Makita’s offerings, these appear to be significantly superior.

Refined the compound miter cutting jig & Demo. :Ms. Moroi

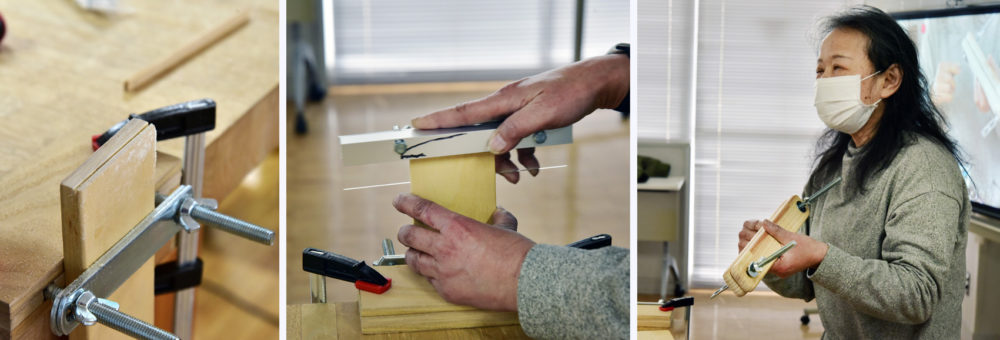

Ms Moroi has refined the compound miter cutting jig previously presented by Mr Sugita. The key improvement involves securing the inclined workpiece directly with F-clamps when pressing it against the jig. Furthermore, when cutting the groove of the base plate, the workpiece must also be kept at an angle, and this too is secured directly with clamps. This method ensures the workpiece is firmly fixed, preventing any movement whatsoever during cutting or groove cutting, thereby enhancing machining precision.

Introduce a tray using the compound miter cutting jig: Mr. Umemura

Mr Umemura also built a tray using the compound miter cutting jig. I believe adopting the clamping method for the workpiece using the compound miter cutting jig presented by Ms Moroi this time would further improve accuracy. The small parts visible at the back of the tray are corner blocks made by gluing together offcuts left after cutting the workpiece to size, used during gluing. Clamping is done with a belt clamp. Corner splines can be seen at the corners.

Present his tool cabinet design: Mr. Dalton

Mr Dalton presents his tool cabinet design. It involves fixing narrow angle bars (sliding rails) inside the carcase to support the drawers.

Unless made of plywood, drawer bottoms expand and contract repeatedly. Mr Dalton devised his own method to accommodate this movement. While biscuit joints are sometimes used for joining boards, this method employs screw washers instead. Using a slot cutter with a blade width nearly matching the washer’s thickness, crescent-shaped slots are cut into both sides of the opposing wood edges. The washer is then inserted into these slots. When the wood expands, the gap between the edges closes; when it contracts, a gap opens. Consequently, the wood edges do not bond.